20

2015

Coefficient of Friction Testing Equipment – Aluminum Foil Test

i-COFTEK 3300 Coefficient of Friction Testing Equipment is designed to determine static and dynamic coefficient of friction tests of plastic films, sheets, rubber, paper, paper board, PP woven bags, fabric style, and metal-material belts for communication cable, conveyor belts, wood, coatings, brake pads, windshield wipers, shoe materials and tyres, etc. Additionally the instrument could be used to test the smoothness of cosmetics, eye drops and other daily chemical products.

B: Mount the test specimen. The connection of load cell and sled should conform to specific standards.

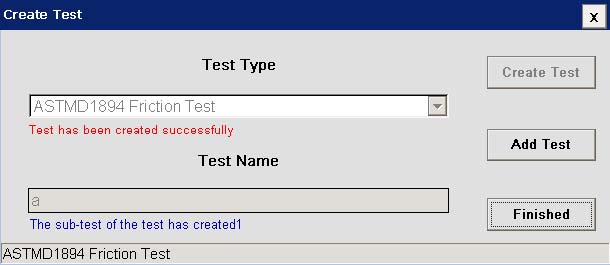

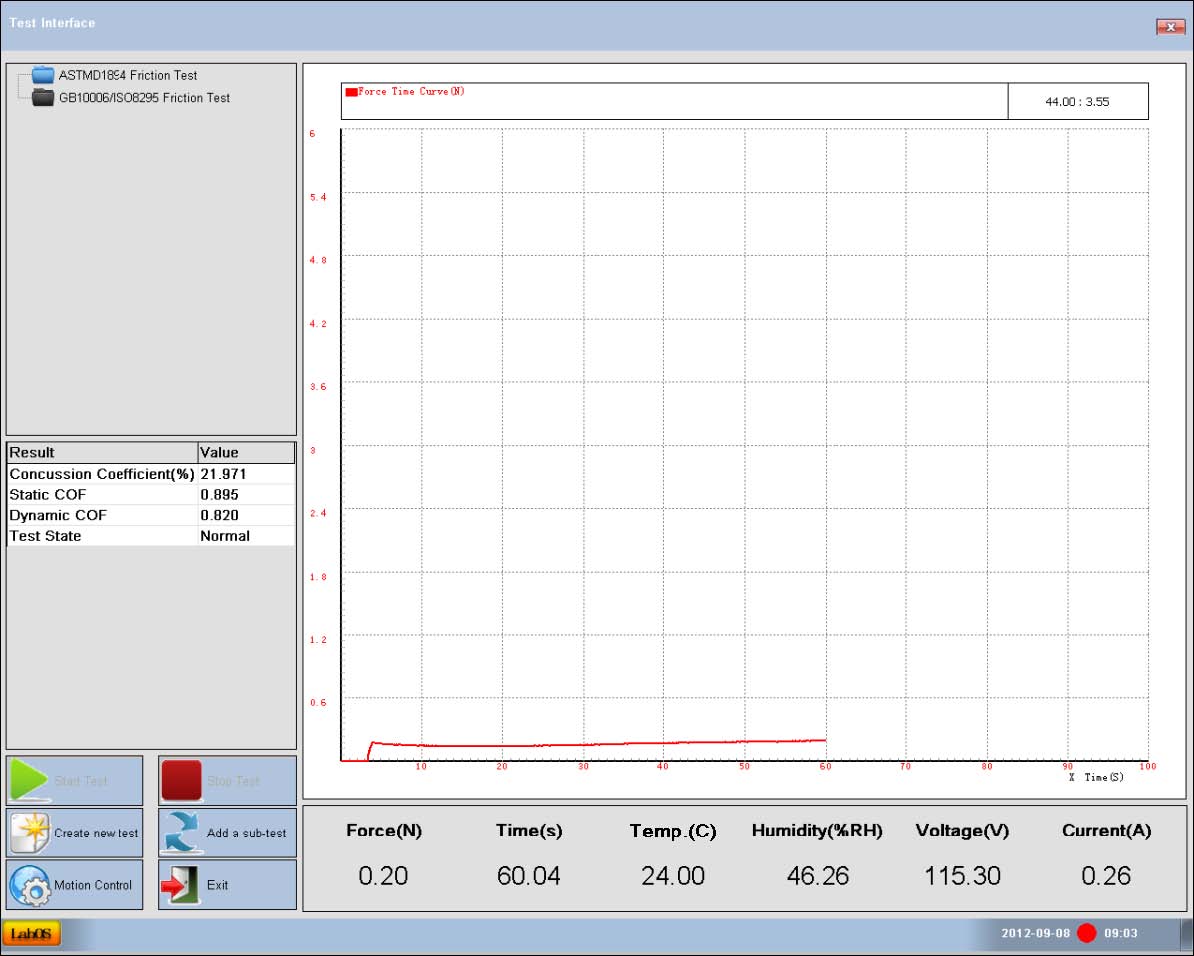

C: Set up test parameters, specimen parameters and then start the test.

D: Record the test data and view the test curve. If the test curve is not satisfactory, the test should be abandoned and new test with another specimen should be started

Leave a comment

Videos for Friction Tester

Recent Posts

- Coefficient of Friction Test of Paint Film or painted panels

- The Significance and Test Method of Coefficient of Friction of Medical Gloves

- Labthink upcoming events, unmissable exhibitions!

- What are the Uses of the Coefficient Of Friction Tester

- Precision Slide Angle Coefficient of Friction Testing by Labthink

An article by

An article by